Product Information

Undercarriage Parts

We continue to supply parts

to support domestic construction equipment quality

Major products

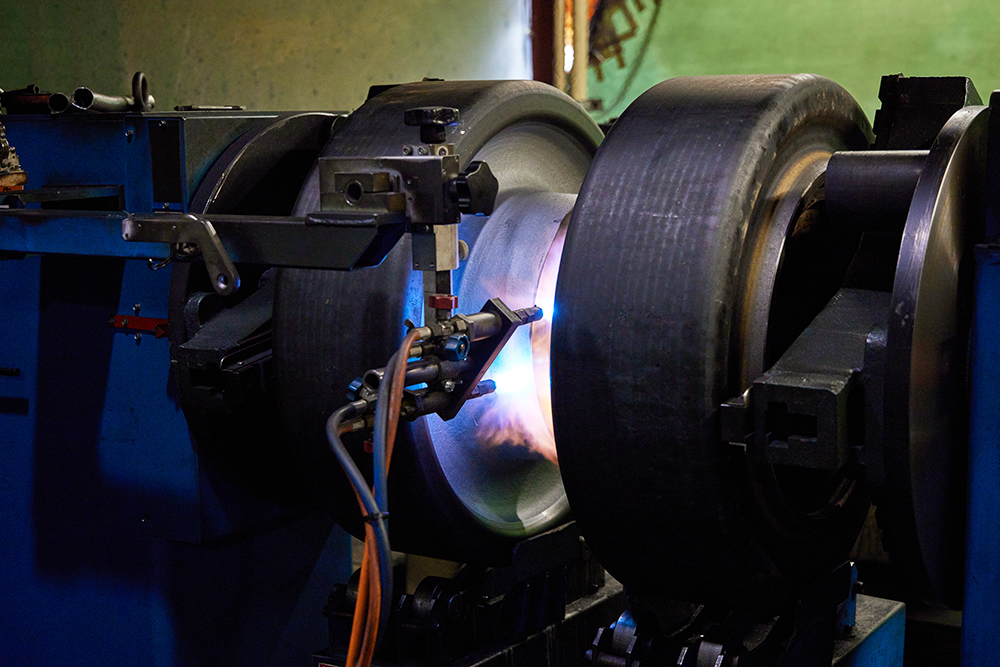

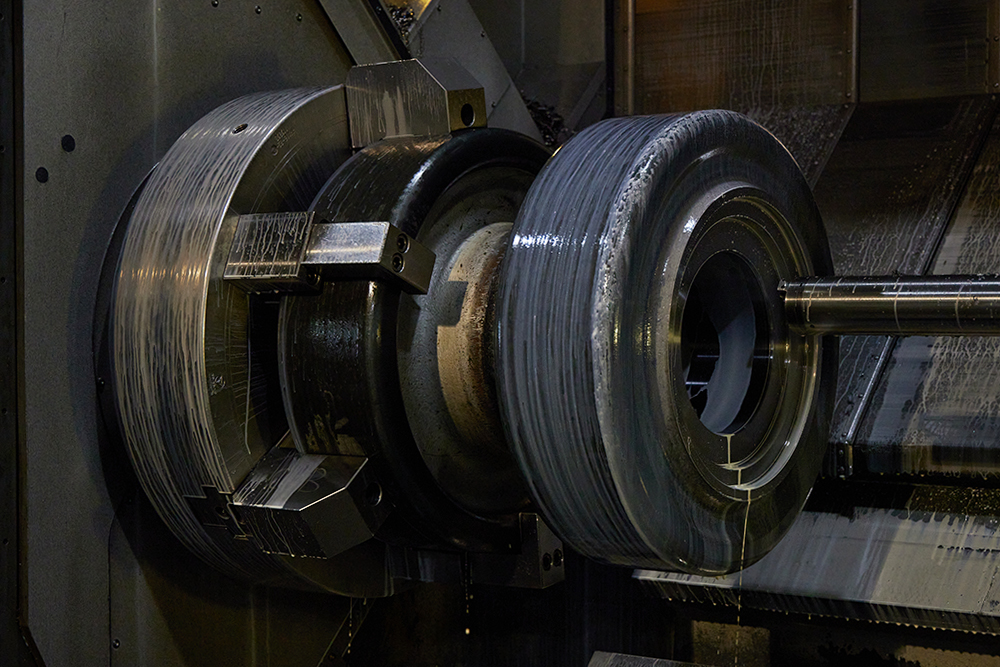

Our high-quality construction machinery undercarriage parts are manufactured using the experience and technologies we have developed over many years. Each part that uses special steel as a material is made using advanced heat treatment, while roller connection areas are made using “friction pressure welding,” which we were the first in the world to develop.

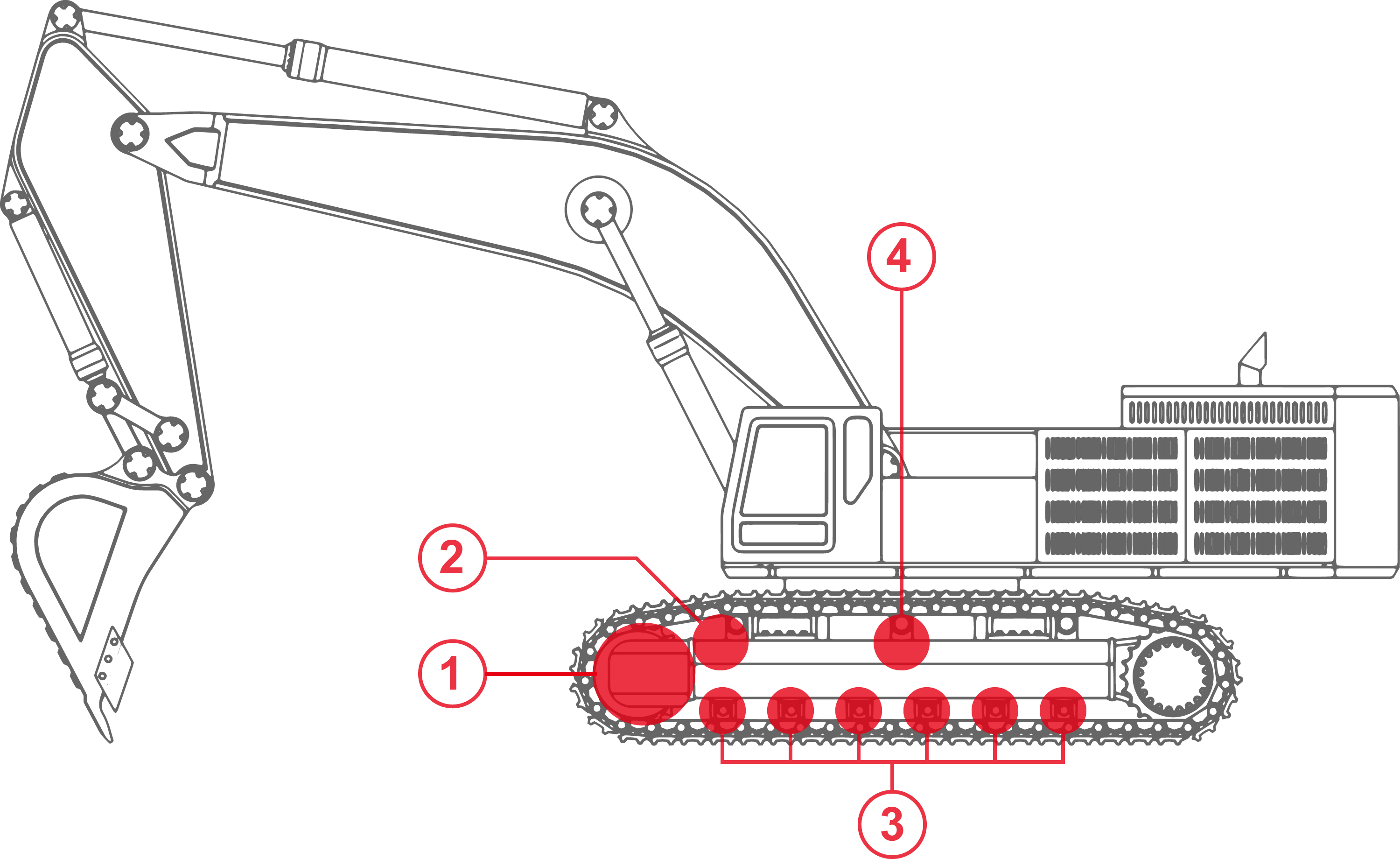

1

Front idler

2

Yoke

3

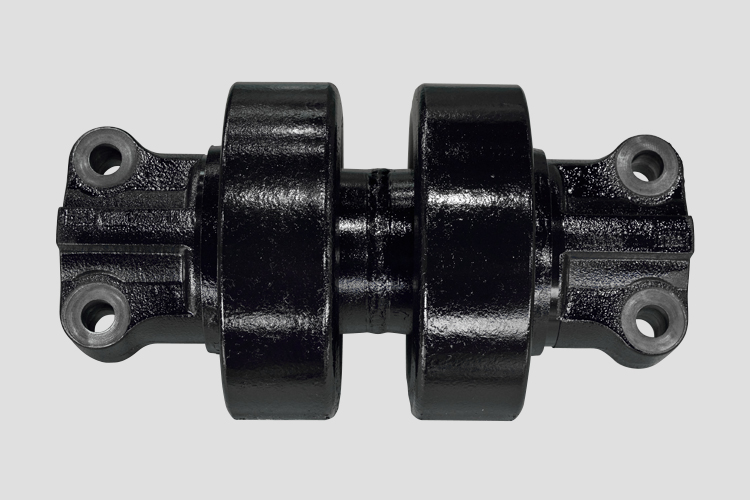

Track roller

4

Carrier roller

Rollers

We offer a selection of rollers compatible with machinery ranging in size from 3-ton class mini-excavators to 800-ton class mining equipment

Triple flanges

Casting-integrated triple flanges

Shaking rollers

Lower dump rollers for uneven ground

Track rollers

Lower rollers for cranes

Track loader idlers

5-ton class

For use with both castings and plate working

Plate working idlers

Rimmed idler wheels for plate working, designed to fit the shape of the track link

Yokes

Casting parts to support tension equipment

Flanges

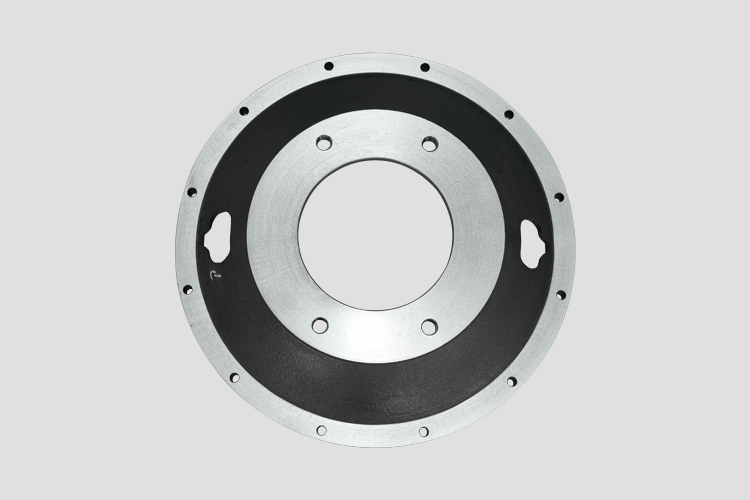

Used for mounting diesel engine hydraulic pumps

Technology and quality

Taiheiyo Seiki manufacturers products in the pursuit of world-class quality. Our high-quality materials and parts (such as seals) are obtained through our supply chain management system, while our rotating and sliding mechanisms are designed by expert engineers, and manufactured within our manufacturing system that makes use of advanced production technologies and quality management.

Products we have manufactured

Please feel free to contact us for information on products outside of the specifications and dimensions listed below.

Our organization can design and machine products to suit your requirements.

Track Roller

| Class | Total length | Roller diameter | Roller width | Remarks |

|---|---|---|---|---|

| 2 to 800 tons | 169 to 976 mm | 107 to 640 mm | 112 to 612 mm |

Carrier Roller

| Class | Total length | Roller diameter | Roller width | Remarks |

|---|---|---|---|---|

| 4 to 800 tons | 160 to 592mm | 83 to 410mm | 103 to 390mm |

Front idlers

| Class | Total length | Roller diameter | Roller width | Remarks |

|---|---|---|---|---|

| 3.5 to 80 tons | 240 to 490 mm | 442 to 875 mm | 100 to 266 mm | Small: Casting Large: Fabricated |